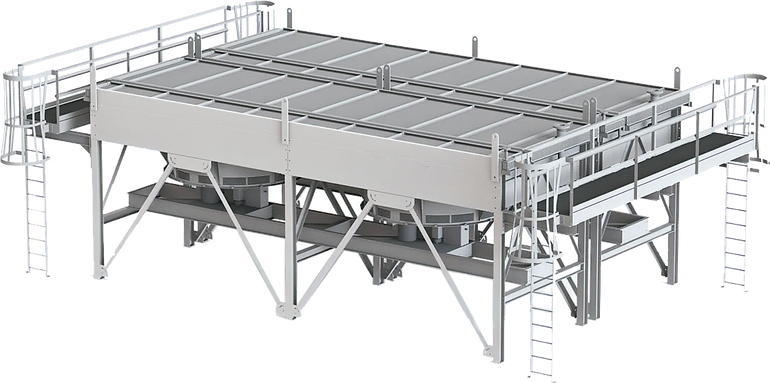

Air-Cooled Heat Exchangers

Air cooled heat exchangers are a vital technology in the oil and gas industry, particularly for upstream and midstream operations where process fluids and gases must be cooled efficiently. Unlike water-cooled systems, air cooled heat exchangers use ambient air as the cooling medium, which makes them especially valuable in remote or arid locations where water supply is limited or unavailable.

In oil and gas applications, air cooled heat exchangers are commonly employed for:

-

Gas Compression: Cooling compressed natural gas or other process gases after compression, helping to maintain equipment reliability and process efficiency.

-

Engine and Generator Cooling: Removing excess heat from engines and generator sets used for onsite power generation, ensuring optimal performance and preventing overheating.

-

Condensate Cooling: Reducing the temperature of hydrocarbon condensates before storage, transport, or further processing.

-

Process Fluid Cooling: Managing temperatures in critical upstream and midstream process streams, such as those found in gathering, processing, and transmission facilities.

The primary advantages of air cooled heat exchangers in oil and gas settings include their ability to operate independently of water resources, reduced risk of fouling or scaling, lower maintenance requirements, and robust performance in harsh environments. Their modular and compact design also makes them well-suited for installations where space is at a premium or where operational flexibility is needed to accommodate variable process conditions.